|

| 4g93T engine halfcut from lancer. |

|

What Is a Turbocharger?

Turbochargers are a type of forced induction

system. They compress the air flowing into the engine . The advantage of compressing the

air is that it lets the engine squeeze more air into a cylinder, and more air means that more fuel can be added. Therefore,

you get more power from each explosion in each cylinder. A turbocharged engine produces more power overall than the same engine

without the charging. This can significantly improve the power-to-weight ratio for the engine.

In order to achieve this boost, the turbocharger uses the exhaust flow from the engine to spin a turbine,

which in turn spins an air pump. The turbine in the turbocharger spins at speeds of up to 150,000 rotations per minute

(rpm) -- that's about 30 times faster than most car engines can go. And since it is hooked up to the exhaust, the temperatures

in the turbine are also very high.

~How Turbochargers Work~

To prevent most failures, may we offer the following suggestions:

Change the oil at least every 3,000

miles, or more frequently if you wish.

Always use the oil that is recommended by the engine manufacturer.

Do

not use cleaning additives for it may loosen particles in any used engine.

Always let the engine warm up when starting.

30-60 seconds in warmer weather and longer as the temperature drops.

COLD, THICK OIL DOES NOT FLOW AS FREELY AS WARM

OIL!

Do not rev engine during warm up time, the turbo may not yet have received a full supply of oil.

Always

let the engine idle for a period when stopping. The faster you have driven, the longer you should let it idle down.

YOUR

TURBO IS FREE SPINNING AT HIGH RPMS WHEN THE ENGINE IS SHUT OFF THE OIL SUPPLY IS ALSO

SHUT OFF, WHICH MAY RESULT IN BEARING

DAMAGE ALMOST IMMEDIATELY.

When oil is changed, always prime the filter and crank over engine without starting until

oil pressure is observed.

By following these suggestion, and practicing good driving habits, your turbo should last

as long as the engine

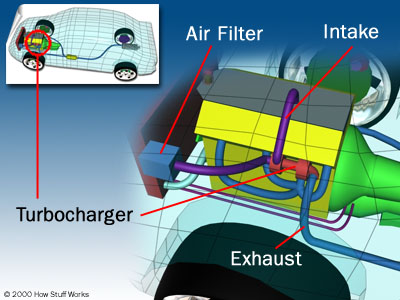

Where the turbocharger is located in the car

Basics

One of the surest ways to get more power out of an engine is

to increase the amount of air and fuel that it can burn. One way to do this is to add cylinders or make the current cylinders

bigger. Sometimes these changes may not be feasible -- a turbo can be a simpler, more compact way to add power, especially

for an aftermarket accessory.

Turbochargers allow an engine to burn more fuel and air by packing more into the existing cylinders. The typical

boost provided by a turbocharger is 6 to 8 pounds per square inch (psi). Since normal atmospheric pressure is 14.7 psi at

sea level, you can see that you are getting about 50 percent more air into the engine. Therefore, you would expect to get

50 percent more power. It's not perfectly efficient, so you might get a 30- to 40-percent improvement instead.

One cause of the inefficiency comes from the fact that the power to spin the turbine is not free. Having

a turbine in the exhaust flow increases the restriction in the exhaust. This means that on the exhaust stroke, the engine

has to push against a higher back-pressure. This subtracts a little bit of power from the cylinders that are firing at the

same time.

Turbos on High

A turbocharger helps at high altitudes, where

the air is less dense. Normal engines will experience reduced power at high altitudes because for each stroke of the piston,

the engine will get a smaller mass of air. A turbocharged engine may also have reduced power, but the reduction will be less

dramatic because the thinner air is easier for the turbocharger to pump.

Older cars with carburators automatically increase the fuel rate to match the increased

airflow going into the cylinders. Modern cars with fuel injection will also do this to a point. The

fuel-injection system relies on oxygen sensors in the exhaust to determine if the air-to-fuel ratio is correct, so these systems

will automatically increase the fuel flow if a turbo is added.

If a turbocharger with too much boost is added to a fuel-injected car, the system may not provide enough fuel

-- either the software programmed into the controller will not allow it, or the pump and injectors are not capable of supplying

it. In this case, other modifications will have to be made to get the maximum benefit from the turbocharger.

Too Much Boost

With air being pumped into the cylinders under pressure

by the turbocharger, and then being further compressed by the piston , there is more danger of knock. Knocking happens because as you compress air, the temperature of the air increases. The temperature may increase

enough to ignite the fuel before the spark plug fires. Cars with turbochargers often need to

run on higher octane fuel to avoid knock. If the boost pressure is really high, the compression ratio

of the engine may have to be reduced to avoid knocking.

Turbo Lag

One of the main problems with turbochargers is that they do

not provide an immediate power boost when you step on the gas. It takes a second for the turbine to get up to speed before

boost is produced. This results in a feeling of lag when you step on the gas, and then the car lunges ahead when the turbo

gets moving.

One way to decrease turbo lag is to reduce the inertia of the rotating parts, mainly by reducing their

weight. This allows the turbine and compressor to accelerate quickly, and start providing boost earlier.

Small vs. Large Turbocharger

One sure way to reduce the inertia of the

turbine and compressor is to make the turbocharger smaller. A small turbocharger will provide boost more quickly and at lower

engine speeds, but may not be able to provide much boost at higher engine speeds when a really large volume of air is going

into the engine. It is also in danger of spinning too quickly at higher engine speeds, when lots of exhaust is passing through

the turbine.

A large turbocharger can provide lots of boost at high engine speeds, but may have bad turbo lag because of

how long it takes to accelerate its heavier turbine and compressor.

In the next section, we'll take a look at some of the tricks used to overcome these challenges.

Intercoolers

When air is compressed, it heats up; and when air heats

up, it expands. So some of the pressure increase from a turbocharger is the result of heating the air before it goes into

the engine. In order to increase the power of the engine, the goal is to get more air molecules into the cylinder, not necessarily

more air pressure.

|

| How a turbocharger is plumbed (including the charge air cooler) |

An intercooler or charge air cooler is an additional component that looks something like a radiator, except air passes through the inside as well as the outside of the intercooler. The intake air passes through sealed

passageways inside the cooler, while cooler air from outside is blown across fins by the engine cooling fan.

The intercooler further increases the power of the engine by cooling the pressurized air coming out of the

compressor before it goes into the engine. This means that if the turbocharger is operating at a boost of 7 psi, the intercooled

system will put in 7 psi of cooler air, which is denser and contains more air molecules than warmer air.

|